The P-Series Systems

200 Liters

WP1-P2-200

Technical Data

Filtered Oil Flow (l/h): 200-240

Viscosity (cSt) 0-220

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 225

Dimensions HxWxD (mm): 440x425x280

Weight (kg): 26

Materials: AISI 304 Stainless

Filter Cannister (liter): 1×8

Alarm: Option

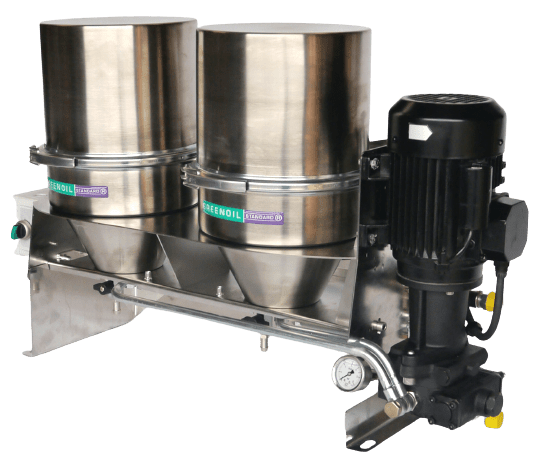

400 Liters

WP1-P2-400

Technical Data

Filtered Oil Flow (l/h): 400-480

Viscosity (cSt) 0-220

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 550

Dimensions HxWxD (mm): 510x920x281

Weight (kg): 36

Materials: AISI 304 Stainless

Filter Cannister (liter): 2×8

Alarm: Option

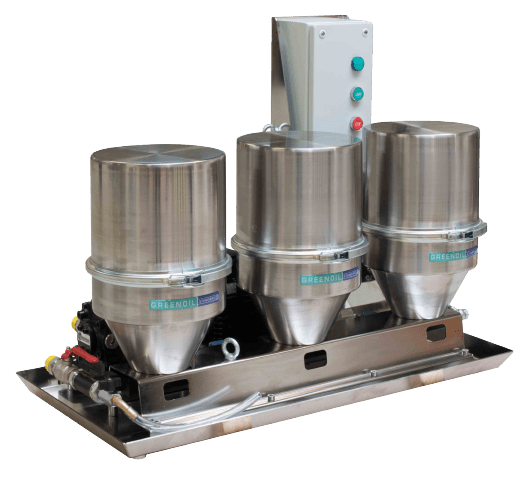

750 Liters

WP1-P3-750

Technical Data

Filtered Oil Flow (l/h): 750-900

Viscosity (cSt) 0-220

Power Suppl (Vac-Hz): 3×400/440 or 3×690-50/60

Max Power Consumption (W): 1100

Dimensions HxWxD (mm): 660x880x281

Weight (kg): 73

Materials: AISI 304 Stainless

Filter Cannister (liter): 3×8

Alarm: Option

1000 Liters

WP1-P3-1000

Technical Data

Filtered Oil Flow (l/h): 1000-1200

Viscosity (cSt) 0-220

Power Suppl (Vac-Hz): 3×400/440 or 3×690-50/60

Max Power Consumption (W): 1100

Dimensions HxWxD (mm): 660x1150x441

Weight (kg): 85

Materials: AISI 304 Stainless

Filter Cannister (liter): 4×8

Alarm: Option

1500 Liters

WP1-P3-1500

Technical Data

Filtered Oil Flow (l/h): 1300-1560

Viscosity (cSt) 0-220

Power Suppl (Vac-Hz): 3×400/440 or 3×690-50/60

Max Power Consumption (W): 1100

Dimensions HxWxD (mm): 660x1150x441

Weight (kg): 85

Materials: AISI 304 Stainless

Filter Cannister (liter): 4×8

Alarm: Option

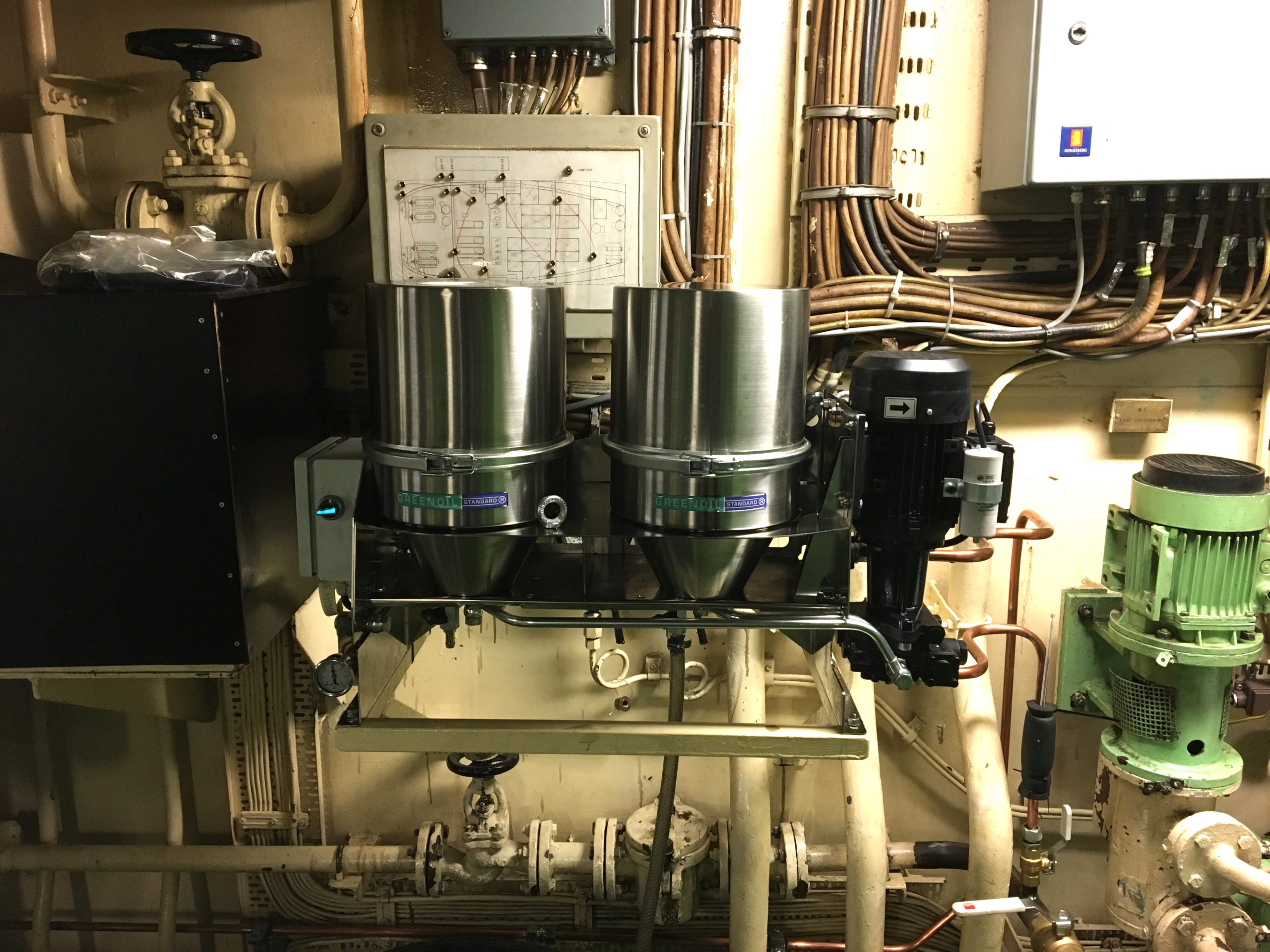

“This system is performing much better than we expected when we bought and installed the system. We have now after 3000 engine operating hours replaced the filter elements. We use only a small amount of lub. oil and we have no sludge waste product. We are happy about the service provided and performance. We would certainly recommend this system.”

WP1-P2-400 installed onboard Viking Line – Amorella

Filtration for Lubrication Oil

Performance to rely on

GreenOil offline oil filtration system for lubrication oil gives you quality oil filtration. It is the most efficient particle filtration system on the market.

The benefits of proper lubrication filtration are many, but the most important ones are as following:

- Improved environmental footprint

- Lower energy consumption and operational costs

- Improved oil quality

- Uncomplicated installation and compact design

- No need to preheat the oil

- No risk of water contamination

Additionally the GreenOil solution comes with several green advantages, such as low power consumption, no oil spill nor sludge production. The cost efficient solution, which even has an average payback time of less than a year in most cases.

The Technology Behind the Solution

Today, an engine require optimal cleanliness levels. The GreenOil solution improves the vessel’s lubrication oil to the best possible quality through efficient particle filtration and water separation, thus protecting the engine from unnecessary breakdowns in order to gain optimal, safe and reliable operation. GreenOil Standard offers an efficient particle filtration system for all vessel types operating on any fuel, both as retrofit solutions and for newbuilds, to improve the oil quality and keep it within the engine manufacturer’s specified requirements. Thereby, ensuring no contaminants enters the engines sensitive parts, protecting the equipment from any unnecessary wear and tear.

WANT TO HEAR MORE ABOUT WHAT WE CAN DO FOR YOUR COMPANY?

Send your contact details and we will get back to you as soon as possible.

“GreenOil is an innovative company, passioned and specialized in oil filtration. Our patented solutions are well proven, and are recognized as efficient, economical and sustainable solutions, which have resulted in satisfied and loyal customers.“

Location

Erhvervsparken 10

8400 Ebeltoft

Denmark

Contact Us

Email: info@greenoil.dk

Phone: +45 87 52 00 84

Fax: +45 87 52 00 85