The C-Series Systems

125 Liters

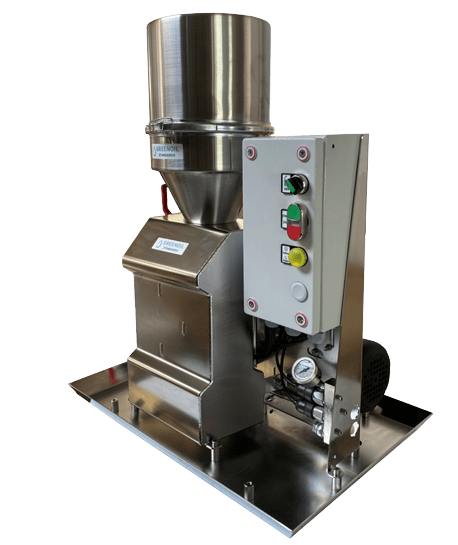

WP1-C1-125

Technical Data

Filtered Oil Flow (l/h): 125-150

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 250

Dimensions HxWxD (mm): 440x425x280

Weight (kg): 26

Materials: AISI 304 Stainless

Filter Cannister (liter): 1×8

Pressure and Water Alarm: Option – Pressure only

250 Liters

WP1-C1-250

Technical Data

Filtered Oil Flow (l/h): 250-300

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 250

Dimensions HxWxD (mm): 440x425x280

Weight (kg): 26

Materials: AISI 304 Stainless

Filter Cannister (liter): 1×8

Pressure and Water Alarm: Option – Pressure only

500 Liters

WP1-C4-500

Technical Data

Filtered Oil Flow (l/h): 500-600

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 550

Dimensions HxWxD (mm): 775x635x435

Weight (kg): 47

Materials: AISI 304 Stainless

Filter Cannister (liter): 1×8

Pressure and Water Alarm: Option

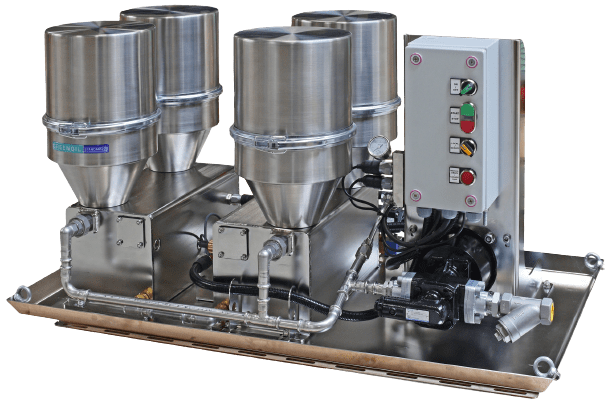

1000 Liters

WP1-C4-1000

Technical Data

Filtered Oil Flow (l/h): 1000-1200

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 1×230, 3×400/440 or 3×690-50/60

Max Power Consumption (W): 550

Dimensions HxWxD (mm): 775x820x435

Weight (kg): 78

Materials: AISI 304 Stainless

Filter Cannister (liter): 2×8

Pressure and Water Alarm: Option

1500 Liters

WP1-C4-1500

Technical Data

Filtered Oil Flow (l/h): 1300-1560

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 3×400/440 or 3×690-50/60

Max Power Consumption (W): 550

Dimensions HxWxD (mm): 775x1105x435

Weight (kg): 85

Materials: AISI 304 Stainless

Filter Cannister (liter): 3×8

Pressure and Water Alarm:

2000 Liters

WP1-C4-2000

Technical Data

Filtered Oil Flow (l/h): 2000-2400

Viscosity (cSt) 0-25

Power Suppl (Vac-Hz): 3×400/440 or 3×690-50/60

Max Power Consumption (W): 750

Dimensions HxWxD (mm): 605x1090x640

Weight (kg): 92

Materials: AISI 304 Stainless

Filter Cannister (liter): 4×8

Pressure and Water Alarm: Option

Two WP1-C1-1000 installed onboard the yacht Cocoa Bean

Filtration for Diesel

Performance to rely on

GreenOil offline oil filtration system for diesel combines oil filtration with our unique water separation method, giving you quality oil filtration. It is the most efficient combined particle filtration system with patented water separator on the market for marine diesel (MDO) and marine gas oil (MGO).

The benefits of proper diesel filtration are many, but the most important ones are as following:

- Minor oil loss and sludge production

- Lower energy consumption and operational costs

- Improved oil quality

- Uncomplicated installation and compact design

- Improved environmental footprint

The system is designed, so both large and small particles are filtrated, before the water is bound together, creating sufficient density for treating. Once the water is separated, the unique water separator is designed to demist any water contamination, trapping the water, and permitting the oil to pass.

Results have shown cleanliness levels down to ISO 15/14/12 and water below 100ppm.

The Technology Behind the Solution

Our C-series systems can be placed in the fuel transfer system between the settling/bottom tank and the service/day tank or alternatively as an offline system in either tank used to recirculate oil. A GreenOil system can be offered either as a retrofit and a new build. The unit removes particles and water from oil and comprises of a pump and motor unit, a GreenOil filter and a built-in water separator. This results in clean oil ready for use. Even suitable for those applications with a sensitive fuel or high-pressure system.

WANT TO HEAR MORE ABOUT WHAT WE CAN DO FOR YOUR COMPANY?

Send your contact details and we will get back to you as soon as possible.

“GreenOil is an innovative company, passioned and specialized in oil filtration. Our patented solutions are well proven, and are recognized as efficient, economical and sustainable solutions, which have resulted in satisfied and loyal customers.“

Location

Erhvervsparken 10

8400 Ebeltoft

Denmark

Contact Us

Email: info@greenoil.dk

Phone: +45 87 52 00 84

Fax: +45 87 52 00 85