GreenOil Optimize the Operation of the DFDS Fleet

Onboard the Ro-Ro ship Ark Germania 15 Greenoil systems are installed. They maintain the oil quality of many critical oil applications onboard.

Saved Power and Maintenance Costs Led to a Replacement of Separators

Onboard the DFDS Ro-Ro cargo ship Ark Germanina, 15 GreenOil offline oil filtration systems are installed, ensuring that the cargo safely arrives in either Esbjerg or Immingham harbor. The systems are distributed on six different applications onboard the Ark Germanina: thrusters, controllable pitch propeller, gearbox, steering gear, hydraulic ramps and stern tubes. The majority of these installation have been used since 2014, when the ship was put into operation. Most recently, the ship’s three auxiliary engines have been fitted with GreenOil systems based on the successful performance of the other six applications.

»We are now able to primarily use GreenOil filters for cleaning the lubrication oil from our three auxiliary engines, because of the auxiliary engines’ few operating hours. It results in great expenditure cuts, when the separator is not needed. This process both saves power to the separator and maintenance costs« – Chief engineer Per Severinsen, who shares the daily technical responsibility with his colleague chief engineer Jeppe Nissen-Jørgensen in a 14-day rotation.

The comparison of a separator and a GreenOil system, showed DFDS the benefits of the new approach to oil filtration. One of the main concerns when choosing a new technology is the investment. For Ark Germania’s investment on the three auxiliary engines a return of investment was calculated as a period of 12 months. The short ROI resulted in two areas of optimization. The great expenditure cuts concerning the old separators, as it has now been activated since the GreenOil filters were installed. Secondly, the minimal expenses concerning the replacement of the filter cartridges on the GreenOil system. Contrary to the separator, the GreenOil systems does not need to heat the oil, thereby saving energy and money. Additionally the filtration process in a GreenOil system is more smooth than when filtrating using a separator, thereby minimizing the risk of damaging the oil.

The annual operating costs for the separator is estimated at 12,000 USD, while the operating costs of three GreenOil filters are 3,900 USD. That is a significant difference of 8,100 USD.

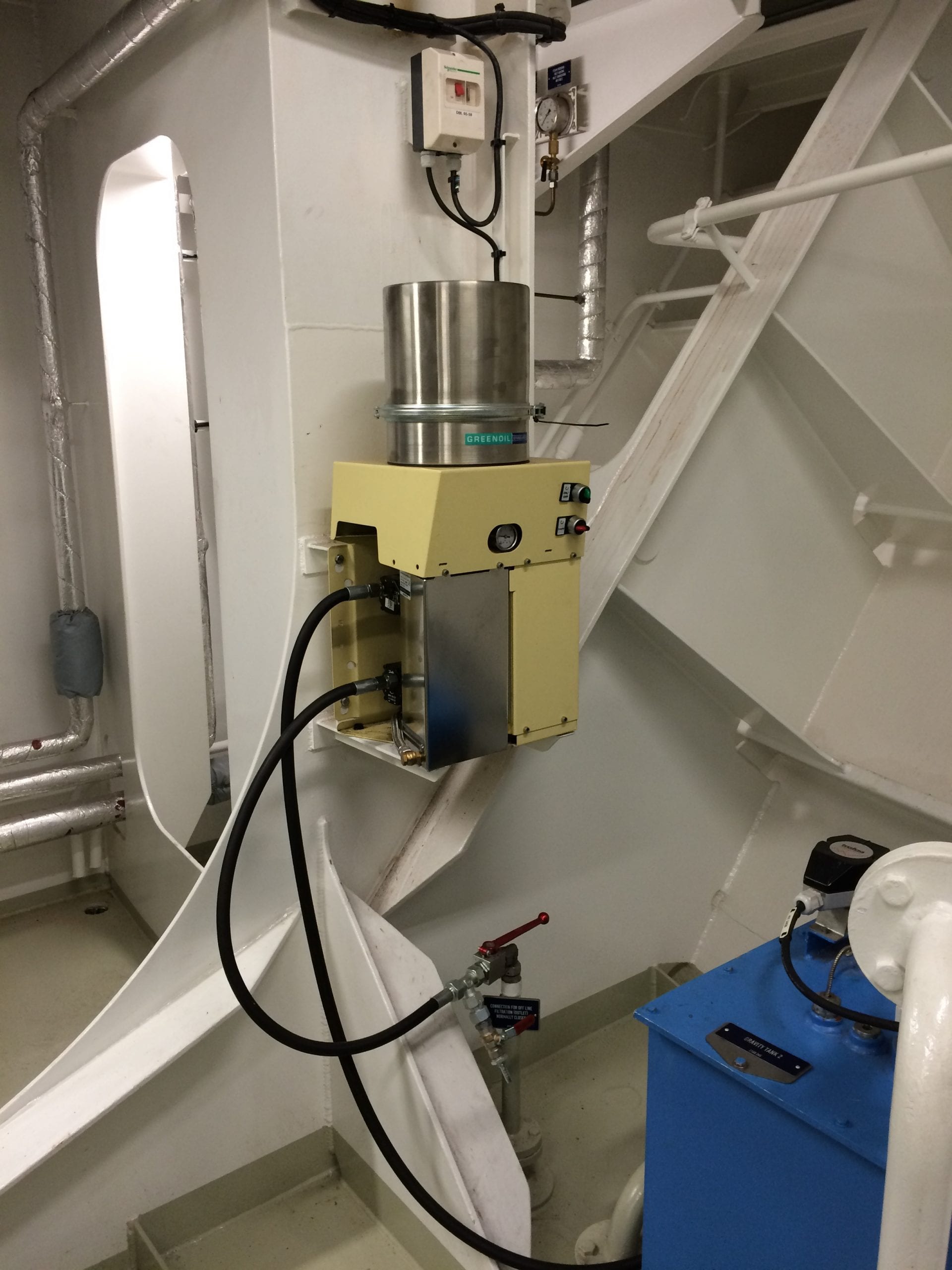

Three GreenOil WP1-P1-100 systems are installed for each of the three Aux. Engines, which are into the operation instead of the purifiers.

Removal of Particles and Water

GreenOil filters are providing filtration of particles and water separation in Ark Germania’s thrusters, gearbox, steering gear, CPP, hydraulic ramps and stern tubes. It is the unique and patented solution which ensures an efficient water separation and a continuous supply of clean oil. In the auxiliary engines, the primary concern is particles causing unnecessary attrition of the components, which can affect the quality and longevity of the oil. Therefore, the primary process is particles filtration, removing particles down to 2 my from the oil. GreenOil systems extend the life time of the oil onboard due to the high-quality filtration.

»We have found the GreenOil filters on board Ark Germania very satisfactory, and it corresponds to the experience on board other ships in the DFDS fleet, where they use the GreenOil filters as well« – chief engineer Per Severinsen.

GreenOil filters accomplish this task completely satisfactory, in the daily operation on board the Ark Germania – in addition, they ensure reliability, minimal energy consumption and easy installation.

GreenOil filters installed onboard Ark Germania

3 filters on each of the 3 Aux. engines, used instead of existing purifier/separator

2 filters on each of the 2 Thrusters

2 filters on each Controllable Pitch Propellers

2 filters on each of the 2 Gearboxes

4 filters on the 2 Steering gears

1 filter for the Hydraulic ramps

1 Mobile filter unit for Stern tubes

Different types of oil

There are many positive sides effects to clean oil, one of them is the effect visibly seen on components which are in direct contact with the oil such as pumps, engines and bearings. The cleaner the oil is, the less wear and tear are seen on components. In collaboration with GreenOil, The Chiefs on Ark Germania have found the right system and filter inserts for all types of oil onboard, namely lubrication oil, hydraulic oil and gear oil. In addition to prolonged lifetime for the vessels components, the advantages found onboard are low acquisition and operation costs as well as effortless maintenance with no oil contact nor physical contact with the oil.

»Each type of oil requires a special filter cartridge that GreenOil provides, and which we have in stock on board, so we always have them ready, whenever we need to change the filter cartridge«

– Per Severinsen.

GreenOil WP1-B1-230 system installed on Steering Gear.

Effortless maintenance

GreenOil makes oil filtration effortless. Not only is the installation simple, but changing a filter can be done in a manner of minutes. Onboard Ark Germania, the engeineers have installed the systems themselves, systems that are expected to last at least 20 years. Htey have experiences first hand the ease of replacing a used filter insert with a new one, without contact with the oil or a large cleanup job afterwards. Once the filter insert is changed, simply turn on the switch again.

»We just need to keep an eye on the pressure in the filter during our rounds. When the pressure gauge shows a certain pressure, the filter cartridge is replaced. It does not take many minutes and it happens a few times a year« – Per Severinsen.

The GreenOil filters have minimal energy consumption and a pure mechanical functionality. The intention is that service, maintenance and operation should be as effortless and quick for the crew as possible. This is confirmed by the chief engineers from Ark Germania.

»After two years of operation we are very satisfied with the GreenOil filters. There have not been any bad experiences or unpleasant surprises« -Per Severinsen.

Calculated Expenditure Cuts

Annual expenditure cut: 8,100 USD (with the installation of three GreenOil filters instead of a separator) Annual CO2 reduction: 4.5 tons

The advantages of GreenOil filters

– Saves the use of separators on auxiliary engines

– Power saving and less maintenance of separators

– High quality of oil filtration and extended oil longevity

– Simple replacement of the filter cartridges – done in a few minutes and without contact with the oil

– Special filters for all types of oil

– Purely mechanical solution, no electronics

– Low power consumption in the filter

– Simple installation – can be performed by the engine crew

– No maintenance when it comes to water separation – patented solution that removes 250 ml/ day of water

– Simple stainless design with very low maintenance costs

The three auxiliary engines on board Ark Germania are equipped with their own GreenOil filter which clean the lubrication oil on the engines. As a consequence, there is no need for a separator – which provides both energy and maintenance savings.

“GreenOil is an innovative company, passioned and specialized in oil filtration. Our patented solutions are well proven, and are recognized as efficient, economical and sustainable solutions, which have resulted in satisfied and loyal customers.“

Location

Erhvervsparken 10

8400 Ebeltoft

Denmark

Contact Us

Email: info@greenoil.dk

Phone: +45 87 52 00 84

Fax: +45 87 52 00 85